Product Description

The Venom Bite Ceramic 3-Step Diamond Polishing Pads are designed for fabricators who want excellent surface results, smooth blending, and dependable edge performance in one easy-to-run system.

Built on Venom’s crossover ceramic resin formula, Venom Bite bridges the gap between hybrid pads and traditional resin pads, making it a versatile choice for shops working across natural stone and modern hard surfaces.

Venom Bite performs especially well for:

-

Surface scratch repair

-

Blending and touch-ups

-

Flat polishing where clarity matters

-

Controlled, predictable edge polishing

These pads are commonly used on quartz, quartzite, granite, marble, porcelain, Dekton, and other natural or compact surfaces.

Rather than focusing on aggressive edge speed, Venom Bite prioritizes clean finishes, smooth transitions, and consistent results across a wide range of materials.

The Crossover Ceramic Advantage

Venom Bite Ceramic Pads were developed through Venom’s 2024 R&D program to combine the best characteristics of hybrid and ceramic polishing technology.

In real-world use, Venom Bite delivers:

-

Confident edge performance without being overly aggressive

-

Excellent surface scratch repair and blending

-

Smooth transitions and high clarity on flat surfaces

-

Consistent control on quartz, quartzite, porcelain, Dekton, and natural stone

This balance allows many shops to use one pad system for both edge work and surface touch-ups, simplifying daily workflow while still producing professional-level finishes.

Same Performance, Smarter Pad Organization

Venom Bite Ceramic Pads use the same ceramic resin formula, diamond quality, and finishing characteristics as Venom Ceramic Pads.

The difference isn’t performance — it’s workflow.

Venom Bite uses a different pad mold and Velcro color-coding system, helping shops that run multiple Venom pad lines stay organized, grab the correct pads quickly, and avoid mixing systems during daily production.

Same results. Cleaner workflow.

Why Ceramic Resin Works So Well

Ceramic resin pads are known for their ability to polish surfaces while actively removing scratches, making them ideal for crossover applications on both stone and man-made materials.

Ceramic resin:

-

Excels at surface scratch repair and blending

-

Produces excellent face-polishing clarity

-

Blends smoothly without resin smear

-

Performs consistently on flat surfaces and edges

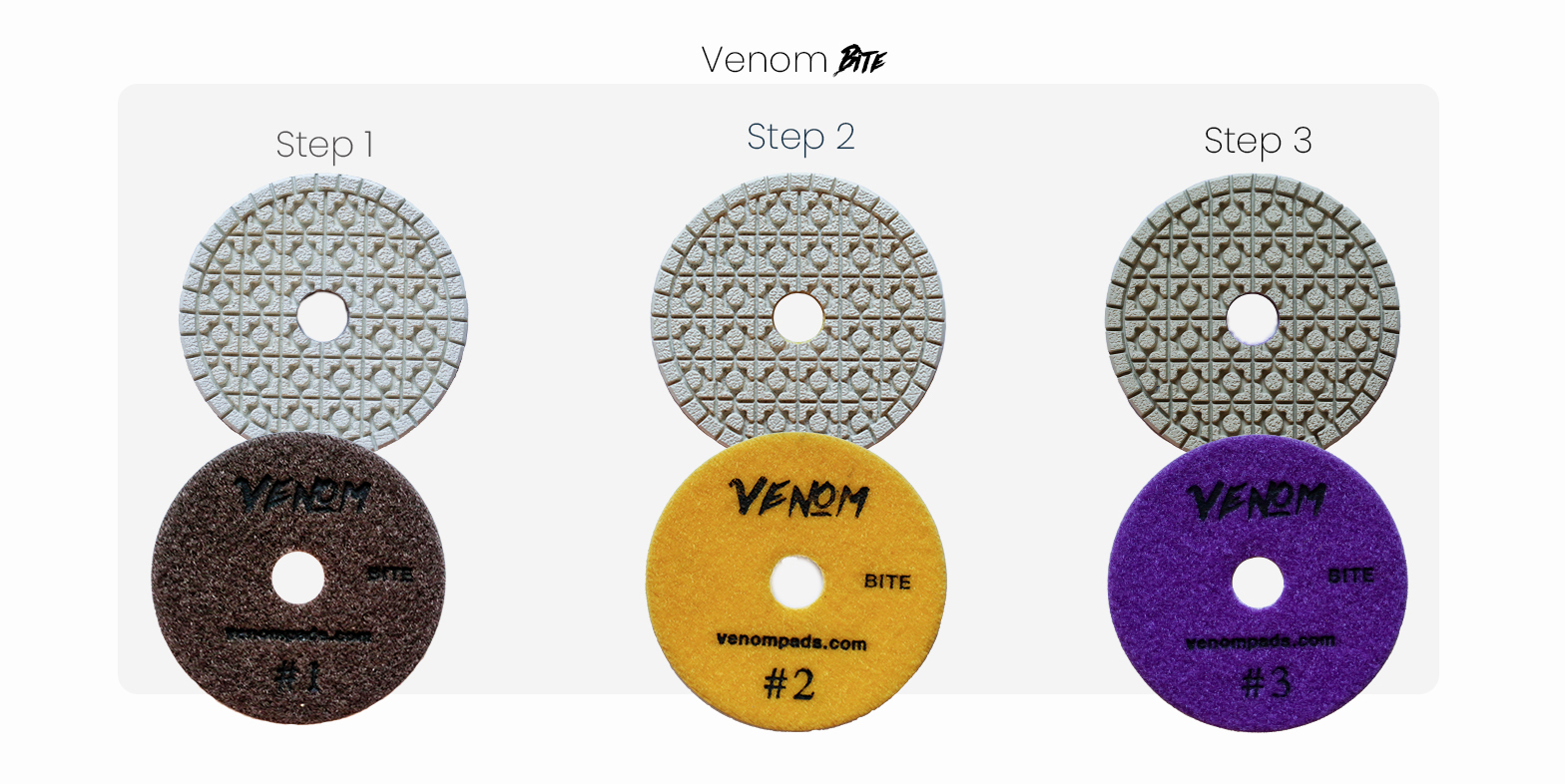

Pad System Layout

Coarse → Step 1 → Step 2 → Step 3 → High Gloss

Steps 1–3 define the core system.

Coarse and High Gloss are optional depending on material condition and desired finish.

Key Features

-

Crossover ceramic resin technology

-

Excellent surface polishing and blending

-

Smooth, controlled edge performance

-

Designed for natural stone and hard surfaces

-

Works on quartz, quartzite, granite, marble, porcelain, Dekton, and compact surfaces

-

Sold and recognized as a true 3-step polishing system

-

Optional Coarse pad for additional stock removal

-

Optional High Gloss pad for added clarity and shine

-

Different mold and Velcro color system for easy pad identification

-

Wet-use only for best results

Wet-Use Design

Venom Bite Ceramic Pads are designed for wet polishing. Using steady water or a controlled mist helps:

-

Keep pads cool

-

Promote even resin breakdown

-

Extend pad life

-

Deliver consistent, repeatable finishes

Primary Applications

-

Quartz countertops

-

Quartzite (natural stone)

-

Granite and marble

-

Porcelain slabs and tile

-

Dekton and compact surfaces

-

Surface scratch repair

-

Blending and touch-ups

-

Edge polishing where finish quality matters

Specifications

-

Resin Type: Ceramic Resin

-

Use: Wet polishing only

-

Diameter: 4 Inch

-

Attachment: Velcro

-

Machine Compatibility: Hand grinders, edge machines, line polishers

RPM & Usage Notes (LOCKED STANDARD)

-

Recommended average speed: ~3,500 RPM

-

Common working range: 2,000–5,000 RPM

-

Maximum speed: Do not exceed 5,000 RPM

Many fabricators adjust RPM, pressure, and water flow based on material hardness, scratch depth, and finish preference. Ceramic resin responds best to steady pressure and consistent water, especially during surface blending.

Available Grits

Coarse • Step 1 • Step 2 • Step 3 • High Gloss