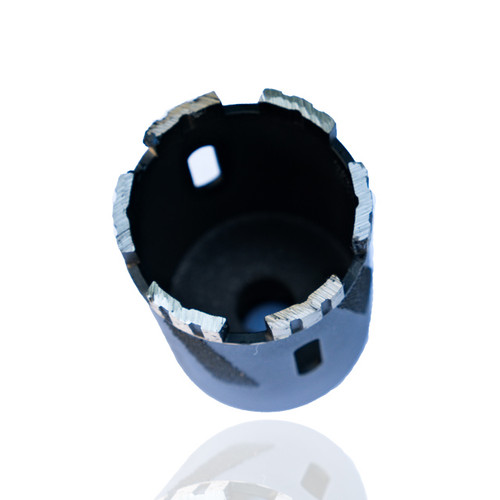

LIGHTWEIGHT STEEL CORE PRECISION DIAMOND MILLING WHEELS

Professional-grade milling wheels designed for quartz, granite, quartzite, engineered stone, and natural stone, built on a Lightweight Steel Core Precision platform that offers exceptional rigidity, accuracy, and long-term stability.

These wheels are perfect for shops wanting maximum precision, aggressive milling, and lower cost compared to silent-core designs — without the heavy weight of old-style steel wheels.

Ideal for slab calibration, heavy stock removal, edge prep, and bridge saw table planing.

WHY LIGHTWEIGHT STEEL CORE PRECISION

-

Most accurate and stable milling performance

-

Lower cost option while still delivering aggressive cutting

-

Stronger rigidity than Teflon Silent Core for ultra-flat milling

-

Only 4% heavier than silent core – almost weight-neutral on modern bridge saws

-

Ideal for hard materials like quartzite & dense granite

SIZES AVAILABLE

-

14 inch (350 mm)

-

16 inch (400 mm)

-

18 inch (450 mm)

THICKNESS OPTIONS

-

3 cm – 1-1/4"

-

4 cm – 1-1/2"

-

5 cm – 2"

ARBOR / BORE

-

50/60 mm Multi-Fit

APPLICATIONS

-

Slab calibration & milling

-

Planing down bridge saw tables for smoother, straighter, more accurate cutting

-

Leveling concrete saw decks

-

Flattening strips, jambs & backsplashes

-

Pre-polish or pre-profile material prep

FEATURES

-

Lightweight Steel Core Precision design

-

Most rigid and accurate milling wheel

-

Lower cost than Teflon Silent Core

-

Long-life aggressive diamond segments

-

Wet-use for bridge saws

-

Excellent on quartz, granite, quartzite & engineered stone

IMPORTANT NOTE – LIGHTWEIGHT STEEL CORE ADVANTAGE

-

The Lightweight Steel Core Precision Milling Wheel provides the highest accuracy and stability of all milling wheels.

-

It is priced lower than the Teflon Silent Core version, making it the best precision-value option.

-

Only 4% heavier than the silent core — nearly the same load on your machine, with added rigidity for extremely flat milling.