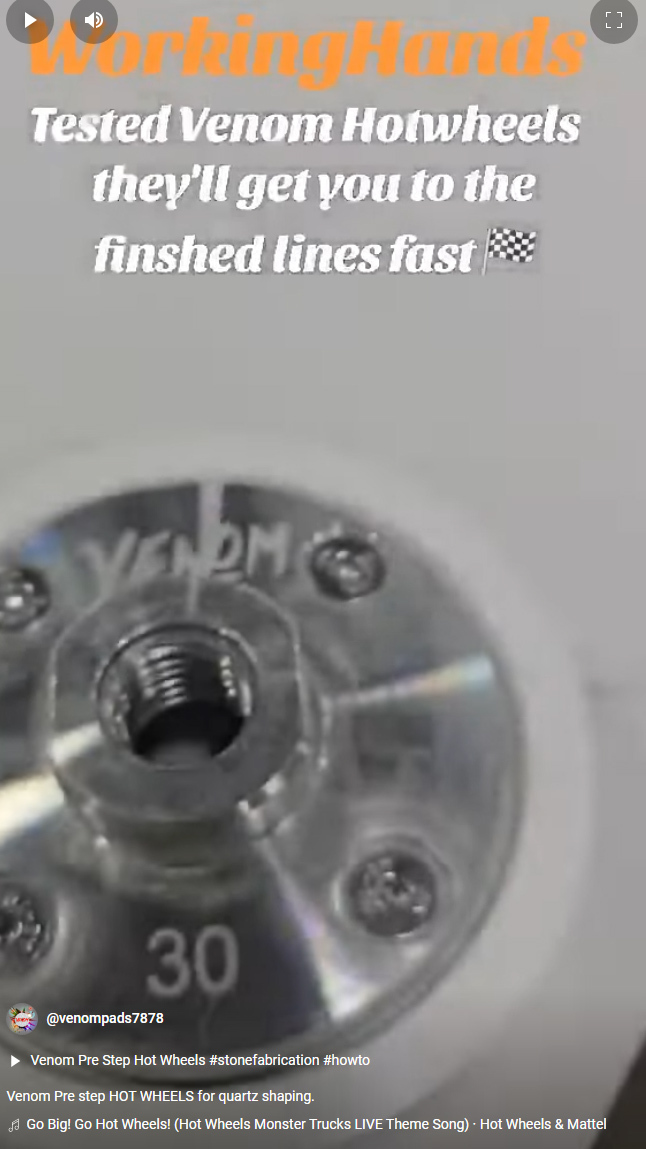

VENOM HOT WHEELS — HYBRID SYNTH DIAMOND RESIN CUPWHEEL FOR TIGHT-RADIUS SHAPING & SINK WORK

Venom Hot Wheels is a next-generation Hybrid Synth Diamond Resin Cupwheel engineered for precision radius shaping, sink cutouts, bowl interiors, seam transitions, and curved stone surfaces.

This advanced HYBRID technology:

• Performs like metal resin wheels

• Performs like continuous rim metal wheels

• But stands in a class of its own

for smoothness, vibration control, and tight-radius shaping.

Designed for professional fabricators who demand cleaner shaping, longer life, and superior control.

WITH STABILIZER RUBBER BACK — NOT ALUMINUM

The new Venom Hot Wheels design includes a Stabilizer Rubber Back, delivering:

✔ Superior balance

✔ Reduced vibration

✔ Cleaner shaping lines

✔ Better control inside sinks

✔ Smoother grinding feel

✔ Less operator fatigue

A major improvement over old aluminum-back designs.

LOW-VIBRATION STABILIZER ENGINEERING

The stabilizer geometry + firm rubber backing keeps Hot Wheels planted during grinding, giving:

✔ No chatter

✔ Precision inside bowl curves

✔ Smoother tight-radius transitions

✔ Better fingertip control

✔ Improved accuracy at all RPM levels

FEATURES & BENEFITS

• Hybrid Synth Diamond Resin Cupwheel Technology

Performs like metal resin AND continuous rim metal wheels —

but with unmatched radius precision and vibration control.

• 10 mm (3/8") Tight-Radius Edge

Ideal for:

• Sink cutouts

• Bowl interiors

• Curved seams

• Tight-radius edges

• Miter transitions

• Available Grits

30 / 50 → aggressive shaping

100 / 200 → seam cleanup, bowl finishing

• White Resin Formula

No staining on light or white stones.

• Material Compatibility

✔ Granite

✔ Quartz (wet only)

✔ Quartzite

✔ Marble

✔ Ultra-Compact Surfaces

• Thread Size

5/8-11 female — industry standard.

RPM GUIDELINES

Recommended Range: 100 – 5,000 RPM

Maximum: Do NOT exceed 5,000 RPM