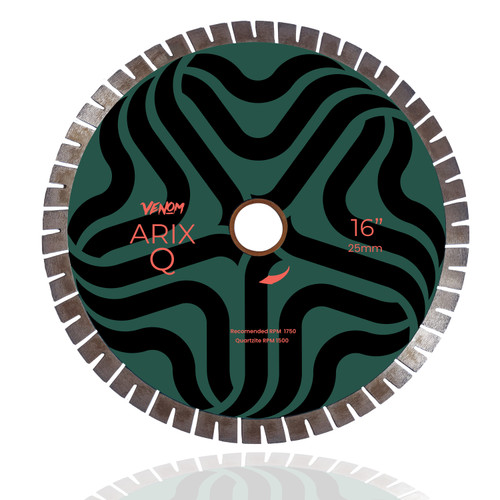

Product Description

The Venom ARIX-Q Diamond Bridge Saw Blade is part of the Venom ARIX Series — a family of professional bridge saw blades that all use the same ARIX layered diamond bond formula, with different segment designs to control cutting speed and cutting behavior.

The ARIX-Q is engineered specifically for faster cutting on quartzite while maintaining strong control and durability. It uses a more aggressive segment design than the HYBRID ARIX blade, allowing it to feed faster through extremely dense stone materials.

Built with ARIX layered diamond technology, this blade continuously exposes fresh diamond as it wears, helping maintain cutting speed and performance throughout the life of the blade. The reinforced silent core reduces vibration and operating noise, resulting in smoother cuts, improved tracking, and better control on demanding quartzite slabs.

What separates the ARIX-Q from typical quartzite blades is its price-to-performance advantage. It delivers true ARIX cutting performance while remaining one of the most cost-effective quartzite bridge saw blades in its class.

Venom ARIX Series Positioning (Important)

All Venom ARIX Series blades use the same ARIX diamond bond formula.

The difference between them is segment design:

• HYBRID ARIX 25mm – Controlled cutting and longer blade life

• Venom ARIX-Q – Faster cutting on quartzite (this blade)

• Venom ARIX Experience – Faster cutting on quartzite

The ARIX-Q is designed for shops that want higher cutting speed on quartzite while maintaining good control and durability.

Primary Application

• Quartzite

Also Performs Well On:

• Quartz

• Granite

Real-World Shop Use (Important)

Although designed for quartzite, many fabrication shops use the Venom ARIX-Q as a crossover blade due to its aggressive cutting behavior. In real-world shop use, it often cuts quartz and granite faster than blades designed only for those materials, reducing blade changes and increasing productivity.

Cutting results depend on stone hardness, saw setup, water flow, and operator technique. Proper feed rates and cooling are essential for best blade life and cut quality.

Choosing the Right Segment Height (Very Important)

The Venom ARIX-Q is available with multiple segment height options so fabricators can match the blade to their cutting style:

15mm Segment – Best for Miters & Straight Cutting

Ideal for shops performing frequent miter cutting. Provides improved control, smoother tracking, and cleaner results on quartzite, quartz, and granite.

20mm Segment – Balanced Option

Best for shops that primarily straight cut but also perform some mitering. Offers a balance of control and segment life.

25mm Segment – Straight Cutting Only

Designed strictly for straight cutting applications. Provides maximum segment life and stability but is not recommended for miter cutting due to reduced control on angled passes.

Straight Cutting vs. Miter Cutting

Segment height plays a major role in quartzite cutting performance. Shorter segments deliver better control for miters and bevels, while taller segments are optimized for straight cutting and extended blade life. Selecting the proper segment height improves cut quality, tool control, and service life.

Blade Construction & Performance

• 16 inch diameter for bridge saw use

• ARIX layered diamond technology

• Silent core for reduced vibration and noise

• Stable tracking for clean, straight cuts

• Designed for professional stone fabrication environments

• Wet cutting recommended

Ideal For

• Shops cutting quartzite daily

• Fabricators needing faster quartzite cutting

• Mixed-material shops (quartz, granite, quartzite)

• High-production environments

• Buyers seeking strong performance without premium pricing